Hotline

13915023276

Summary

The equipment integrates spray, drying, fluidization and granulation. The one-step granulation multi fluid atomizer is more suitable for products with polysaccharide, high viscosity or thermoplasticity. The structure of spray drying chamber, capture chamber, fluidized bed and secondary air supply system has been significantly modified, and the characteristics of spray drying have been appropriately displayed. Design, manufacture, and layout in accordance with GMP requirements. Realize the continuous spray process of the extract, improve the drying intensity of spray, and overcome the "dead bed".

Operational principle

It is suitable for the preparation of traditional Chinese patent medicines and simple preparations; Intermediate, capsule, tablet granules, or coating of granules.

Simultaneously widely used in the one-step granulation and particle coating of liquid materials in the chemical and food industries.

Application scope

Pharmaceutical industry: tablets, granules, capsules, granules; Low sugar, sugar free traditional Chinese patent medicines and simple preparations granules;

Food: cocoa, coffee, milk powder, granulated fruit juice, seasonings, etc;

Other industries: pesticides, feed, fertilizers, pigments, dyes, etc.

Product features

It integrates spray drying/fluidization granulation to realize one-step granulation of liquid materials; It adopts spray process, especially suitable for micro auxiliary materials and heat sensitive materials, and its efficiency is 1-2 times higher than that of FL boiling granulator; Some products have a final moisture content of up to 0.1% and are equipped with a powder return device, with a granulation rate of ≥ 85% and the ability to produce 0.2-2mm particles; Improved design of internal hybrid multi fluid atomizer, capable of handling some specific weights up to 1.3g/cm ³ The extract. At present, this series of products has achieved PGL-150B, and each batch can handle 500kg.

Project | Unit model | PGL-3B | PGL-5B | PGL-10B | PGL-20B | PGL-30B | PGL-80B | PGL-120B | |

Liquid extract | less | kg/h | 2 | 4 | 5 | 10 | 20 | 40 | 55 |

more | kg/h | 4 | 6 | 15 | 30 | 40 | 80 | 120 | |

Boiling ability | less | Kg/batch | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

more | Kg/batch | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

Liquid specific gravity | kg/L | ≤1.30 | |||||||

Quantity of raw material containers | L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

Container diameter | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

Induced draft fan power | kw | 4.0 | 5.5 | 7.5 | 15 | 22 | 30 | 45 | |

Auxiliary fan power | kw | 0.35 | 0.75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

Steam | Consumption | kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

pressure | Mpa | 0.1-0.4 | |||||||

Electric heating power | kw | 9 | 15 | 21 | 25.5 | 51.5 | 60 | 75 | |

Compressed air | Consumption | m3/min | 0.9 | 0.9 | 0.9 | 0.9 | 1.1 | 1.3 | 1.8 |

pressure | Mpa | 0.1-0.4 | |||||||

Operating temperature | ℃ | Room temperature -130 ℃ automatic adjustment | |||||||

Product moisture | % | ≤0.5% | |||||||

Material yield rate | % | ≥99% | |||||||

Equipment noise | dB | ≤75 | |||||||

Host size | Φ | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 |

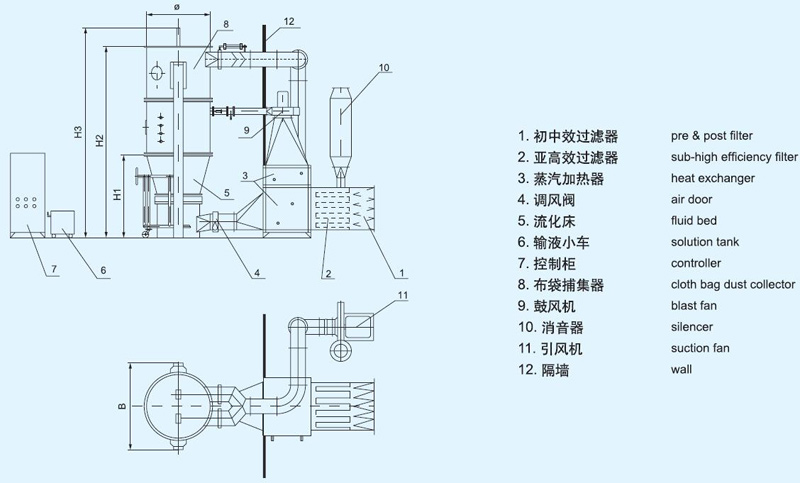

H1 | mm | 940 | 1050 | 1070 | 1180 | 1620 | 1620 | 1690 | |

H2 | mm | 2100 | 2400 | 2680 | 3150 | 3630 | 4120 | 4740 | |

H3 | mm | 2450 | 2750 | 3020 | 3700 | 4100 | 4770 | 5150 | |

B | mm | 740 | 890 | 1110 | 1420 | 1600 | 1820 | 2100 | |

Weight | kg | 500 | 800 | 1200 | 1500 | 2000 | 2500 | 3000 | |

Selection example: It is required that the processing flow extract amount I=120kg (with a solid content of 30%) and the seed amount II=60kg per batch. The theoretical finished product amount M=mI+mII=120kg * 30%+60kg=96kg can be obtained from I and II, and the working time T=120kg/30kg/h=4h. The boiling amount can be found in the technical parameter column as the standard load range. Therefore, it is more suitable to choose PGL-30B type for completing two batches per shift.